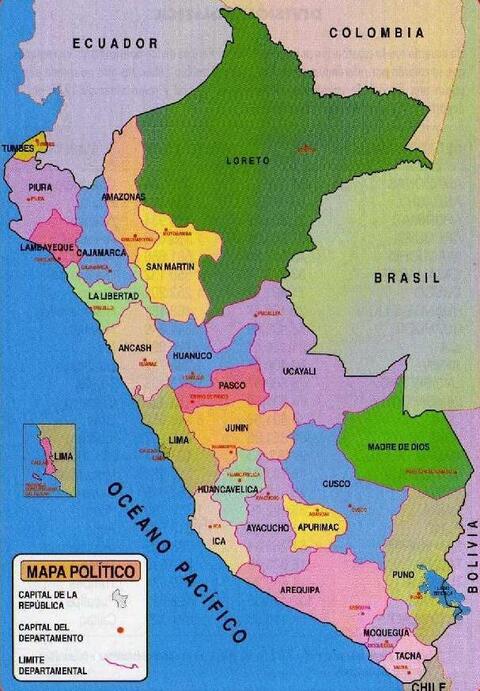

Case Study for the Chiclayo Harbour in Peru

Chiclayo in Lambayeque Province, A coastal town in the north of Peru is 630 US miles from the Capital of Ecuador, Quito, and 500 US miles from Lima the capital of Peru. Very well positioned for the fruit and vegetable and northern mining regions of Peru. The Southern section of the Trans-American Highway runs down the coast from Los Angeles through to Terra del Fuego at the tip of South America.

The Chinese approached us through one of their agencies based in Vienna to review the possibilities of constructing a port.

The challengeS

1. The pacific along this coast was very shallow

2. Chiclayo was a small town with narrow streets

3. Mining operations were in the Andes

4. Seismic movements due to volcanic activities

The mining operations in Bolivia and Argentina sent the raw ore from the mines to the Lima Ports via a slurry pipeline, some to be loaded on the ships bound for China and some to be processed in Lima. Fruit and vegetables were trucked into the Lima Ports for distribution to China and other parts of the world through the Panama Canal, Trucking of Fruit and ore to Liam caused damage to the Trans-American Highway, so a solution had to be found.

The Port:

Studies showed the port had to be located 5 kilometers offshore as the Pacific Shelf was very shallow and would allow for a Panamax 5,000 Twenty-foot equivalent unit containers (TEU), a Dry/Wet bulk carrier, allowing for the length of each ship the port had to be at least 1000 meters in length allowing for maneuvering, each ship is in the region of 350 meters in length. A minimum of 15 meters clearance between the seafloor and the keel had to be considered, as was a Pacific breakwater, container storage areas, offices rest area for the stevedore’s container cranes, and other equipment. A specialist UK firm was contacted who designed and build ports in difficult conditions was contacted their estimate was US$ 500 million for the build and fit-out of the port.

The next challenge was getting the product from dryland to the port, a roadway was out of the question, and the only feasible answer was a specialized container belt system for the containers and below the conveyor belt were the transport capsules for the workers, This would use a considerable amount of energy, however, there was a hydro-electric dam in the local mountains who could provide the electricity at a reasonable cost, provided the port authorities would pay for the cables.

The next two challenges were getting the produce to the port and from the port. Chiclayo is a small town with narrow streets, where container lorries and bulk carrier lorries would not be able to turn corners and heavy traffic would damage the road infrastructures.

The first answer was to build a container park away from the town and close to Pan American Highway. The container park would comprise a receiving area as the conveyor belt would run from the port and the container park a cold storage area as well as a container park.

The second answer to the transfer of ore from the mines was to construct a slurry pipeline directly to the port with a separate pipe for each ore. The Bolivia Pipeline to the lima port is about 300 km and carries one slurry ore. The pipeline would in this case have been 180 km.

The slurry can be directly piped into the ships or into drying-out pans and the ore can then be transferred to a dry bulk carrier.

Whilst the project was registered with the government and local governmental permissions were given, this is South America, the president of Peru resigned and the incoming administration has yet to give permissions to continue.