European Disruptive Manufacturer Case Study

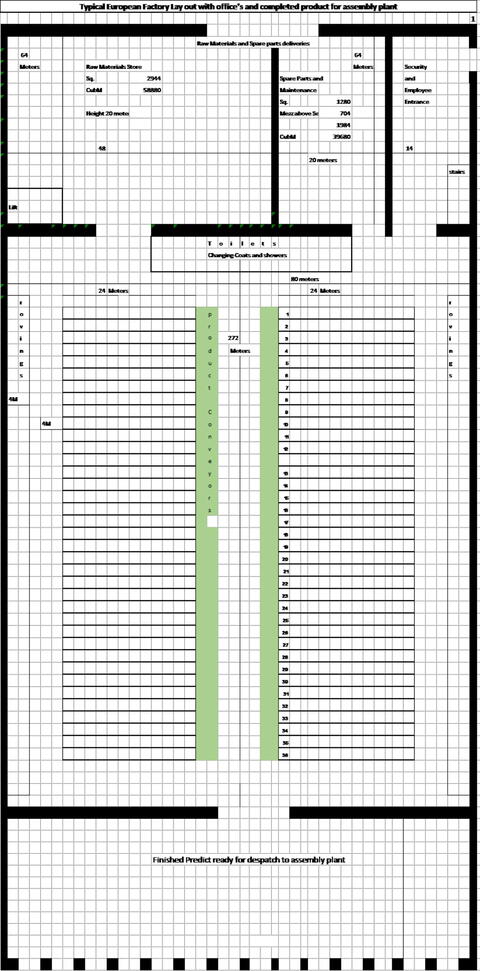

Brief factory layout

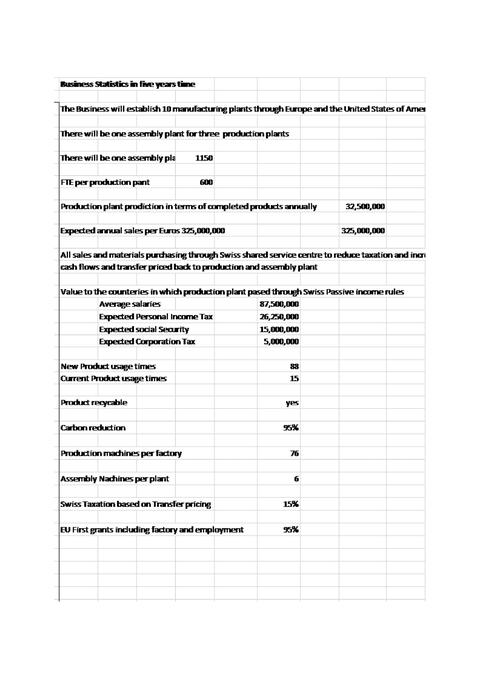

Business statistics in

five years' time

Approach

1. Included a full appraisal of the projects it merits and their deficiencies

2. Deficiencies were found in the business plans, in particular in the presentation of the financials and the way funders viewed financials, there were some corrections to be made in the numbers due to costings, payroll posts, and the number of employees required to run the factories.

3. Operational review, this included machine running speeds, there were four different types of machines to be used including an assembly machine, from this on a 24-hour three-shift system the FTE (Full-time equivalent employees) was calculated, this is based on the production.

4. Optimum design and layout of the factories allowing for machine downtimes and the number of machines required to complete the production process

5. Review of the benefits for the end-user and the effects on wastage and climate changes

6. Review of available grants and applications made for the Grants

7. Assembly Employees - 600

8. Production employees including management – 1170